Failure/Damage Repair

UK MOD (N) type approval underwrites the fact that the Jetpac® product had been proven not to fail when subjected to the test requirements. Therefore the “fit and forget” philosophy pervades. Based on this the UK MOD (N) does not have an issue with failure/damage repair with our product. Indeed, to our knowledge, there has never been a failure in operation of an Oldham Seals Jetpac® product.

Land based or ship based sparing of replacement hoses is a matter of in-service logistical organisation that the UK MOD (N) applies based on certain factors – such as size of ship, and criticality of application. More information on this is contained in Def STAN 02-345.

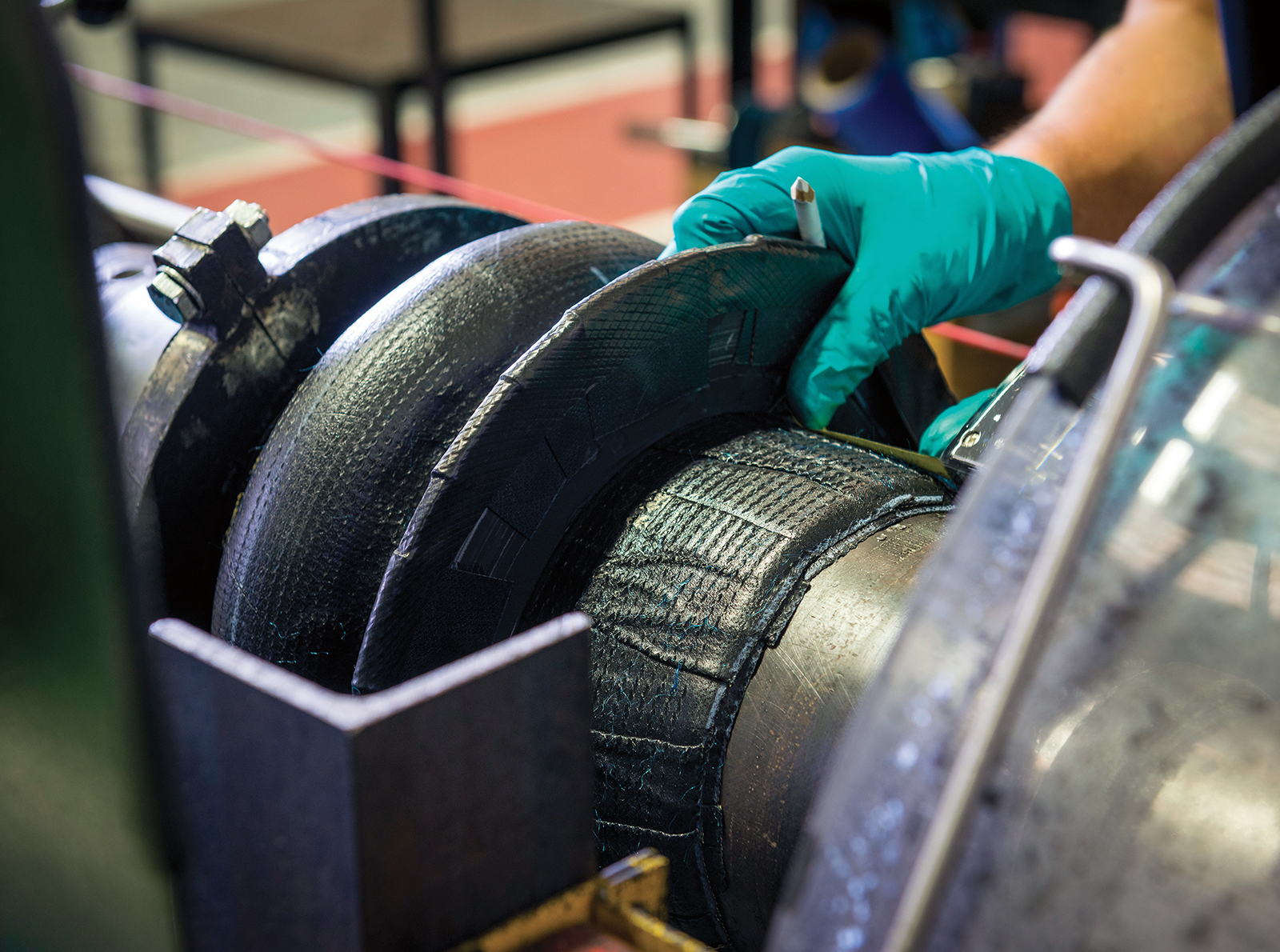

This product confidence has been established and built up during more than 40 years of supply of Jetpac® product by Oldham Seals to the UK MOD (N).

Rating for Service Life

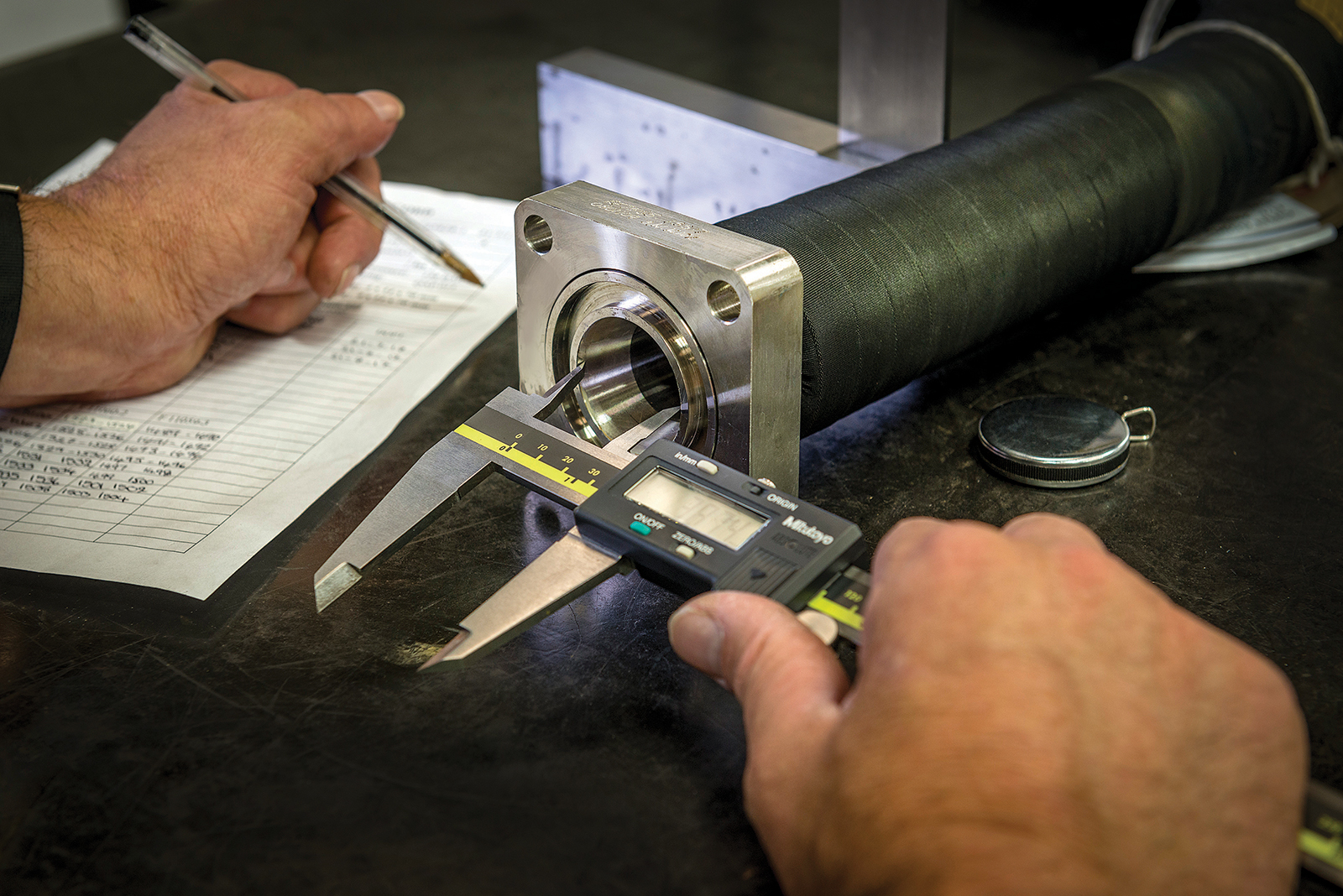

This datum has been established by the UK MOD Navy at 10 years, and vindicated through product type testing. Def STAN 02-345 covers the UK requirement, and using our own in-house test facilities we can product type test, with independent customer verification.

Material Testing is verified independently in the UK by RAPRA (Rubber and Plastics Research Association), and actually forms part of the reporting data for the UK MOD (N).

Our company programme of continued development, improvement and enhancement means that we are sustaining the technology advantage of our products to meet the current and future needs of our customers.